Water treatment equipment

Water treatment equipment

PRODUCTS

Spray tower is a treatment equipment for environmental waste gas treatment, which is divided into circulating water spray tower, alkali spray tower, and acid spray tower according to its working principle. According to the material of the tower body, it is divided into fiberglass spray towers, pp spray towers, and stainless steel spray towers. Choose a reasonable spray tower material and spray process based on the different properties of the exhaust gas.

隐藏域元素占位

UV photooxidation equipment utilizes a specially designed high-energy and high ozone UV ultraviolet beam to irradiate exhaust gas, cracking the molecular chain structure of industrial exhaust gases such as ammonia, trimethylamine, hydrogen sulfide, methyl sulfide, methyl mercaptan, methyl sulfide, butyl acetate, ethyl acetate, dimethyl disulfide, carbon disulfide and styrene, sulfide H2S, VOC, benzene, toluene, and xylene, resulting in organic or inorganic polymer odor compound molecular chains. Under high-energy ultraviolet beam irradiation, Degradation into low molecular weight compounds such as CO2, H2O, etc. Using high-energy and high ozone UV ultraviolet beams to decompose oxygen molecules in the air to produce free oxygen, also known as reactive oxygen species. Due to the imbalance of positive and negative electrons carried by free oxygen, it needs to combine with oxygen molecules to generate ozone.

隐藏域元素占位

Dual medium low-temperature plasma equipment

Low temperature plasma is the fourth state of matter after solid, liquid, and gas states. When the applied voltage reaches the discharge voltage of the gas, the gas is broken down, producing a mixture of electrons, various ions, atoms, and free radicals. In the discharge process, although the Electron temperature is very high, the temperature of heavy particles is very low, and the whole system presents a low-temperature state, so it is called low-temperature plasma. Double dielectric barrier discharge (DDBD) technology can generate large area, high-density low-temperature plasma, which generates particles with high chemical activity, such as high-energy electrons, ions, free radicals and excited state molecules.

隐藏域元素占位

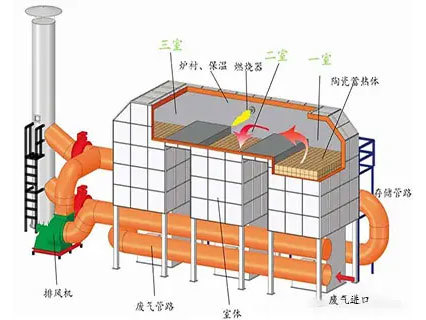

RTO (regenerative thermal oxidation technology)

RTO是指蓄熱式熱氧化技(jì)術(shù),其原理是把有機(jī)廢氣加熱到(dào)760攝氏度以上(shàng),使VOCs氧化分解成二氧化碳和水(shuǐ)。氧化産生(shēng)的高(gāo)溫氣體流經特制的陶瓷蓄熱體,使陶瓷體升溫而蓄熱,此“蓄熱”用于預熱後續進入的有機(jī)廢氣,從(cóng)而節省廢氣升溫的燃料消耗。陶瓷蓄熱體分成兩個(gè)及以上(shàng)的區或室,每個(gè)蓄熱室依次經曆蓄熱-放(fàng)熱-清掃等程序,周而複始,連續工(gōng)作。蓄熱室“放(fàng)熱”後立即引入部分已處理合格的潔淨排氣對蓄熱室進行清掃(以保證VOCs去除率在95%以上(shàng)),“清掃”完成後才能(néng)進入蓄熱程序。

隐藏域元素占位

RCO (Regenerative Catalytic Combustion)

RCO is a new catalytic technology that has the advantages of efficient energy recovery through RTO and low-temperature operation of catalytic reactions. The catalyst is placed on top of thermal storage materials to achieve optimal purification, with a heat recovery rate of up to 95%. The key to the excellent performance of the RCO system is the use of dedicated precious metal or transition metal catalysts impregnated on saddle shaped or honeycomb shaped ceramics. Oxidation occurs at low temperatures of 250-500 degrees Celsius, which not only reduces fuel consumption but also reduces equipment costs.

隐藏域元素占位

Biological deodorization filter

Biological deodorization filter technology is a biological deodorization technology that lies between biological washing method and biological filtration method. The drip filtration tower in the biological deodorization filter technology has both liquid phase regeneration and exhaust gas absorption functions.

隐藏域元素占位

Mobile exhaust gas purification tower

The mobile exhaust gas purification tower is a countercurrent atomization spray tower, filled with special packing. Compared with conventional packing, this packing has advantages such as large specific surface area, high porosity, low resistance, and good wetting performance.

隐藏域元素占位

Mobile exhaust gas adsorption device

The mobile exhaust gas adsorption device is a new generation of odor gas adsorption equipment developed by our company. It is a high-efficiency, economical, and practical organic waste gas filtration and adsorption device. This device has the advantages of high adsorption efficiency, convenient installation and movement, convenient filter replacement, and the ability to simultaneously handle various mixed waste gases.

隐藏域元素占位

Low temperature sludge drying machine

The low-temperature sludge drying equipment utilizes the dehumidification principle of a low-temperature heat pump, and uses convective hot air drying to dry and reduce the weight of the wet material sludge on the mesh belt. The entire system is fully enclosed, and there is no heat loss from the drying hot air.

隐藏域元素占位

Closed reactor fermentation composting equipment

Based on the principle of harmlessness, reduction, and resource utilization, new closed reactor biological composting technology and garden green fertilizer production technology are adopted

隐藏域元素占位

NEWS

undefined

Huanke Environmental Protection Technology

HOTLINE:

Address:Gongye 1st Street, Weicheng District, Weifang City, Shandong Province China

Contact:Zhang Gong

Phone:+86-18865361829

Email:sdhuanke@163.com

Consult

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd