Spray tower

Spray tower is a treatment equipment for environmental waste gas treatment, which is divided into circulating water spray tower, alkali spray tower, and acid spray tower according to its working principle. According to the material of the tower body, it is divided into fiberglass spray towers, pp spray towers, and stainless steel spray towers. Choose a reasonable spray tower material and spray process based on the different properties of the exhaust gas.

Keywords:

Tel:

HOTLINE:400-678-1829

ZHANG GONG:+86-18865361829

詳細介紹

圖文詳情

(1) Equipment Introduction

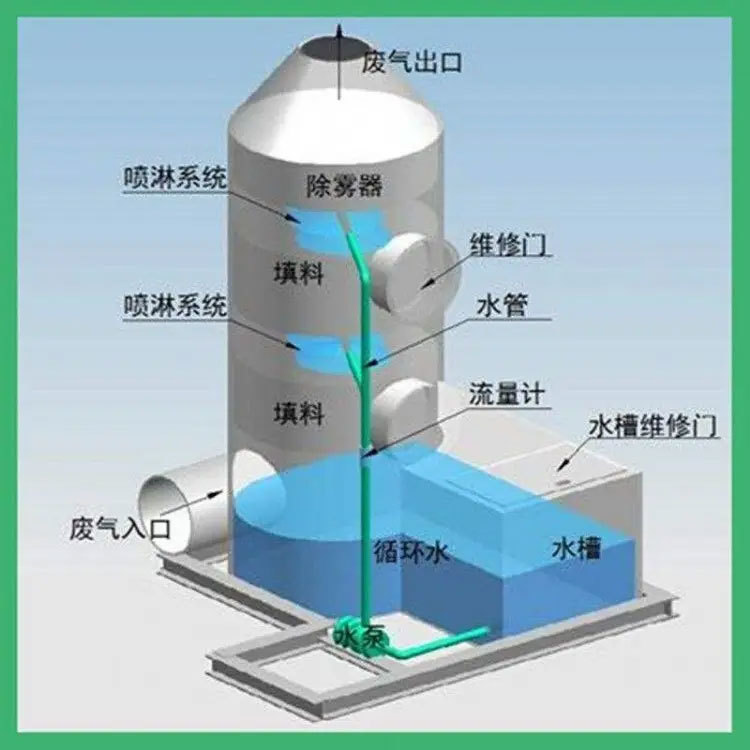

Spray tower is a treatment equipment for environmental waste gas treatment, which is divided into circulating water spray tower, alkali spray tower, and acid spray tower according to its working principle. According to the material of the tower body, it is divided into fiberglass spray towers, pp spray towers, and stainless steel spray towers. Choose a reasonable spray tower material and spray process based on the different properties of the exhaust gas.

When the exhaust gas passes through the spray tower, a suitable position (depending on the design) inside the tower sprays out liquid medium, some of which are alkaline solution and some are sulfuric acid solution. If the exhaust gas contains acidity, choose alkaline solution spraying to neutralize acidity. If the exhaust gas contains alkalinity, choose sulfuric acid solution for absorption. No acid or alkali, but oily or dusty waste gas can be treated by spraying a circulating water solution. When the exhaust gas enters from the bottom of the tower, it comes into contact with the spray medium sprayed out by the spray tower. After contact, the exhaust gas or oil stains are wrapped in water droplets, and the water droplets that wrap the pollutants collide again, increasing the surface area and gravity. Under the influence of gravity, water droplets containing pollutants fall into the bottom of the spray tower when gravity increases. Heavier pollutants settle at the bottom of the tower, while lighter pollutants float on the surface of the circulating water body.

(2) Design considerations

① When the exhaust gas contains oil and dust, it is necessary to consider whether to add filter fillers or nozzle models when designing the spray tower. Choosing an inappropriate nozzle can easily cause blockage in the water system of the spray tower;

② Select appropriate spray media;

③ Design reasonable airflow channels and water supply methods;

④ Sewage discharge and cleaning issues after spraying in the spray tower;

⑤ Appropriate gas-liquid ratio, selecting the appropriate water pump through gas-liquid ratio;

⑥ The flow rate of the empty tower is generally designed to be 1-6 meters per second. However, in the case of medium spraying and filling, the filtering wind speed can be reasonably selected based on the specific situation of the exhaust gas.

(3) Technical parameters

|

NO. |

Specification (mm) | Air volume (m3/h) | Wind pressure (pa) |

|

1 |

Φ800*H2500 |

900~2700 |

250~300 |

|

2 |

Φ1000*H2800 |

1413~3323 |

300~350 |

|

3 |

Φ1200*H2800 |

2034~6102 |

300~350 |

|

4 |

Φ1500*H2800 |

3186~9550 |

350~400 |

|

5 |

Φ2000*H2800 |

5652~16956 |

300~350 |

|

6 |

Φ2500*H2800 |

8820~26460 |

400~450 |

|

7 |

Φ3000*H4500 |

12780~38340 |

450~500 |

ONLINE MESSAGE

*注:請務必信息填寫準确,并保持通(tōng)訊暢通(tōng),我們會(huì)盡快與你取得聯系

相(xiàng)關産品

Huanke Environmental Protection Technology

HOTLINE:

Address:Gongye 1st Street, Weicheng District, Weifang City, Shandong Province China

Contact:Zhang Gong

Phone:+86-18865361829

Email:sdhuanke@163.com

Consult

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd