Low temperature sludge drying machine

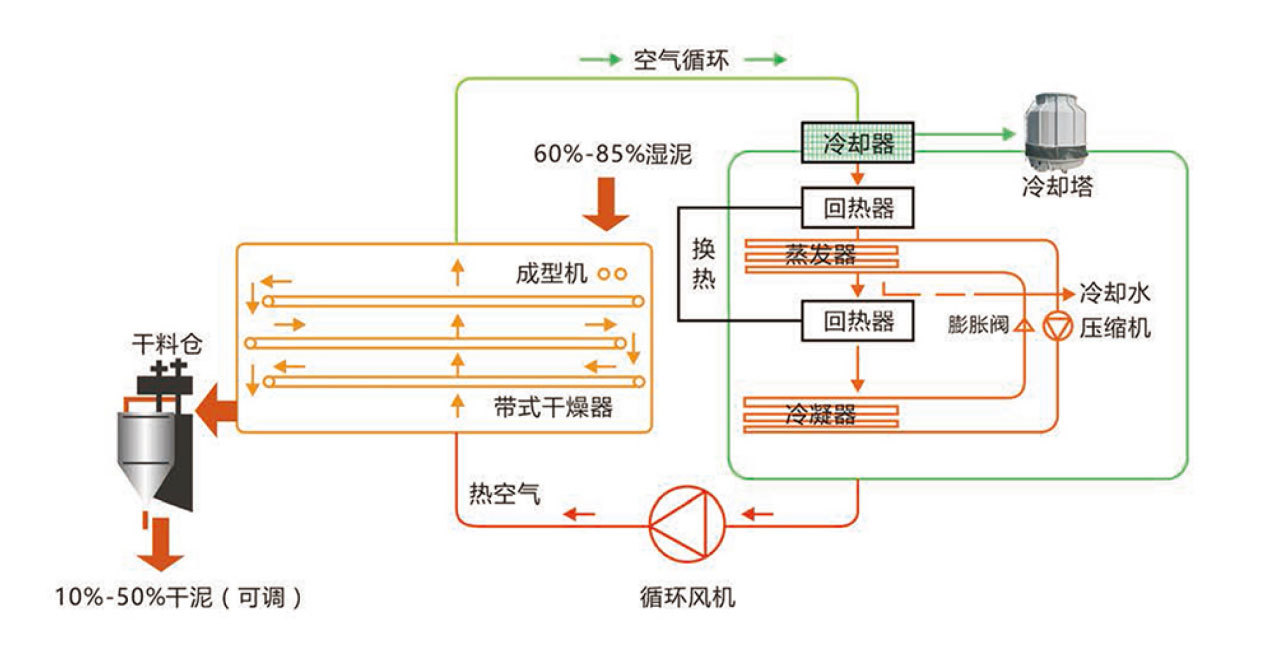

The low-temperature sludge drying equipment utilizes the dehumidification principle of a low-temperature heat pump, and uses convective hot air drying to dry and reduce the weight of the wet material sludge on the mesh belt. The entire system is fully enclosed, and there is no heat loss from the drying hot air.

Keywords:

Tel:

HOTLINE:400-678-1829

ZHANG GONG:+86-18865361829

詳細介紹

圖文詳情

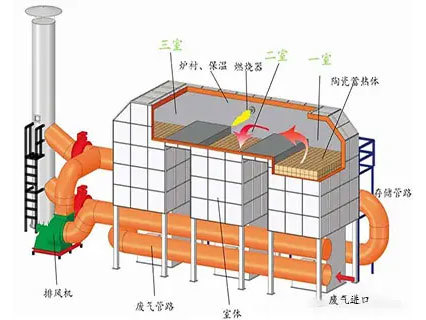

Working principle:

The low-temperature sludge drying equipment utilizes the dehumidification principle of a low-temperature heat pump, and uses convective hot air drying to dry and reduce the weight of the wet material sludge on the mesh belt. The entire system is fully enclosed, and there is no heat loss from the drying hot air.

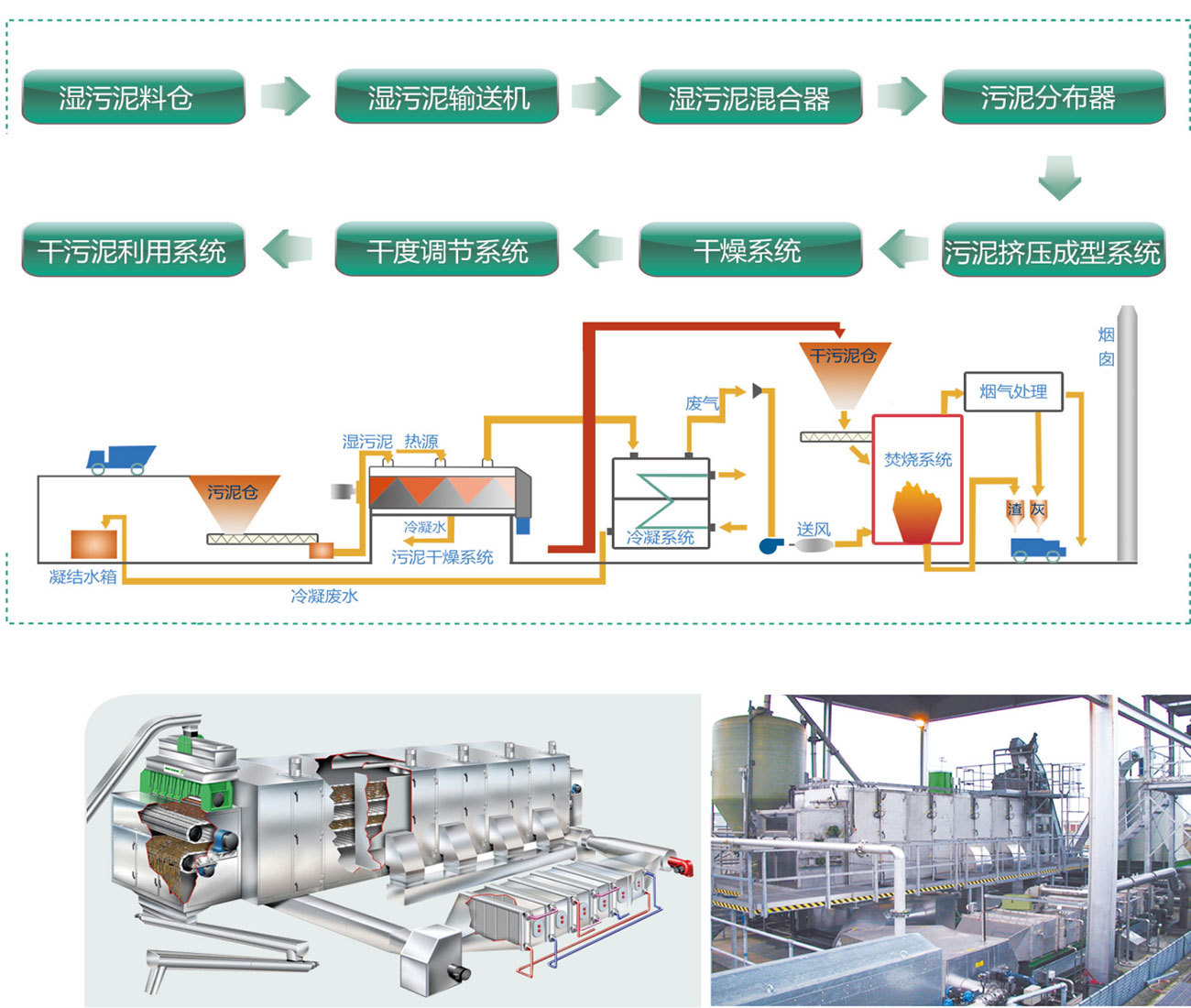

Application scope: It can be widely used for drying and reducing the quantity of urban sludge, industrial sludge, printing and dyeing sludge, pharmaceutical sludge, chemical sludge, leather sludge, electroplating sludge, circuit board sludge, papermaking sludge, coal sludge, etc; Dried sludge with a moisture content of 10% to 30% can be gasified and incinerated for use as biofuels, green soil, recycled cement, or building materials. Realize the reduction, reduction, harmless, stabilization, and resource utilization of various types of sludge in the later stage.

Process Description:

Performance characteristics of waste heat recovery in sludge low-temperature drying machine

1. Low temperature waste heat design, available for flue gas, air compressor waste heat, steam condensate、hot water generated from anaerobic digestion (gas), sludge pyrolysis, gasification and combustion. Provide heat source for equipment;

2. Dry and dehydrate wet sludge with a moisture content of 80% per ton to dry mud with a moisture content of 10%, with a comprehensive operating power consumption as low as 50 kW/h.

3. Modular design, customizable according to capacity matching, simple installation, small footprint, and no complex civil engineering;

4. Suitable for municipal sludge, chemical sludge, electroplating sludge, pharmaceutical sludge, circuit board sludge, printing and dyeing sludge, etc.

5. The moisture content of wet sludge is 83% -40%, and the moisture content of dried sludge is 10% -40%, which can be reduced by 75%;

6. Fully enclosed dehumidification and drying, no exhaust gas, no odor, no odor emission, and no deodorization;

Low energy consumption and power saving, fully automatic operation, simple operation, and convenient maintenance.

ONLINE MESSAGE

*注:請務必信息填寫準确,并保持通(tōng)訊暢通(tōng),我們會(huì)盡快與你取得聯系

相(xiàng)關産品

Huanke Environmental Protection Technology

HOTLINE:

Address:Gongye 1st Street, Weicheng District, Weifang City, Shandong Province China

Contact:Zhang Gong

Phone:+86-18865361829

Email:sdhuanke@163.com

Consult

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd