26

2024

-

01

Selection of ultrafiltration membrane materials

Author:

There are many materials that can be used to manufacture ultrafiltration membranes, including polyvinylidene fluoride (PVDF), polyethersulfone (PES), polypropylene (PP), polyethylene (PE), polysulfone (PS), polyacrylonitrile (PAN), polyvinyl chloride (PVC), etc. In the early 1990s, polyethersulfone materials were commercially applied;

In the late 1990s, polyvinylidene fluoride ultrafiltration membranes with better performance began to be widely used in the water treatment industry. Polyvinylidene fluoride and polyethersulfone have become the most widely used ultrafiltration membrane materials at present.

When ultrafiltration is used for water treatment, the chemical stability and hydrophilicity of its material are the two most important properties. The chemical stability determines the lifespan of membrane materials under the action of acids, alkalis, oxidants, microorganisms, etc., and it also directly affects the selection of cleaning processes; The hydrophilicity determines the membrane material's ability to resist pollutants in water and affects the membrane flux.

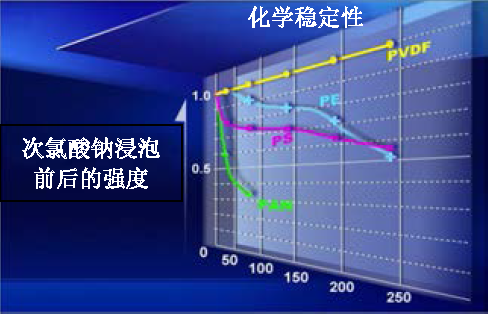

Polyvinylidene fluoride (PVDF) material has the most excellent chemical stability, and its ability to withstand oxidants (such as sodium hypochlorite) is more than 10 times that of materials such as polyethersulfone and polysulfone. In water treatment, microbial and organic pollution is often the main cause of ultrafiltration membrane fouling, and oxidant cleaning is the most effective way to restore ultrafiltration flux. At this time, polyvinylidene fluoride (PVDF) material demonstrates its superiority.

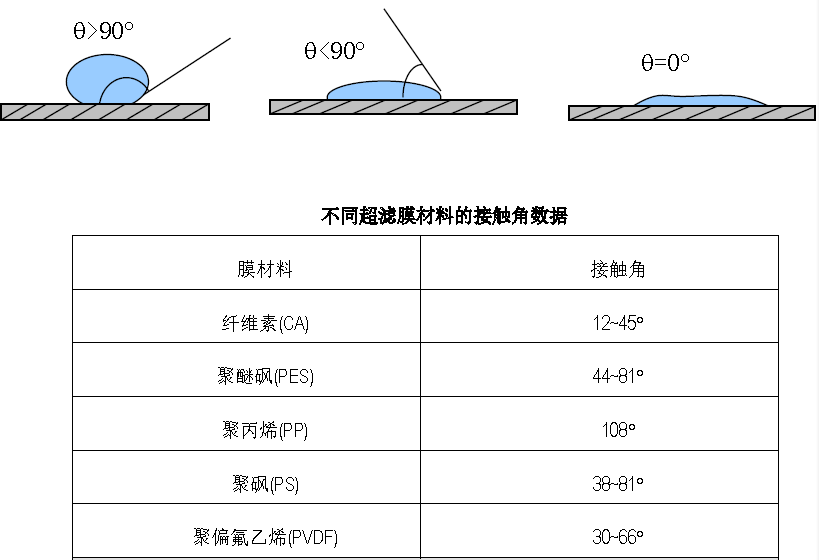

Membrane materials with good hydrophilicity are less prone to contamination and are also easier to clean and recover after contamination. Hydrophilicity is often measured by contact angle.

The meaning of contact angle is shown in the following figure. The larger the value, the more hydrophobic the material is. When it is equal to zero, it indicates that the liquid (water) can infiltrate the solid surface. Here are some data.

A large number of research results have found that using contact angle to evaluate the anti fouling performance of membranes has certain limitations. This is because on the one hand, the measurement data of contact angle itself is not accurate enough, which is influenced by the smoothness of the surface of the tested material, the purity of water, and the measurement technology; On the other hand, when issues such as concentration polarization become prominent, the influence of the membrane's properties takes a back seat.

Related Products

Biological nitrogen removal process of low temperature wastewater

2024-05-28

Prevention and treatment of calcium carbonate scaling in reverse osmosis operation

2024-05-22

Treatment of pyrazolone production wastewater - bipolar membrane electrodialysis process

2024-05-20

How much salt does sewage contain that can enter the biochemical system?

2024-05-17

Huanke Environmental Protection Technology

HOTLINE:

Address:Gongye 1st Street, Weicheng District, Weifang City, Shandong Province China

Contact:Zhang Gong

Phone:+86-18865361829

Email:sdhuanke@163.com

Consult

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd